Report on Industrial Visit, Varun Beverages Pvt Ltd.

On 12th April 2023, 38 students from Universal School of Administration visited 34th K M Stone, NH-4 , Tumur Road, T.Begur Nelamangala, Bengaluru, Karnataka 562123 with faculty co-ordinator Ms. Deepika Vettikuntla, Assistant Professor of Commerce.

The objectives of the visit were to:

1) To orient the students on company history, organization structure and its journey so far.

2) To observe the stages in manufacturing process including procurement of raw materials, bottling and packaging.

3) To observe the quality control and assurance measures, risk control measures taken at the plant.

4) To understand briefly on plant layout, machinery and technology used in the processing.

5) To understand costing methods, process costing, Cost Per Unit (CPU), labour costing, batch costing, cost control and reduction measures used at the unit.

The students and the faculty co-ordinator departed from college campus at 9:45 AM to report to the Varun Beverages pvt ltd location. We arrived in Nelamangala at 10:45 AM post which there was orientation regarding safety standards to be followed while inside the factory premises. All students were checked for compliance of Visitor Guidelines like Covid -19 double vaccination certificate, Identity cards and appropriate footwear. We all filled a self declaration form disclosing our travel history and previous/current medical ailments.

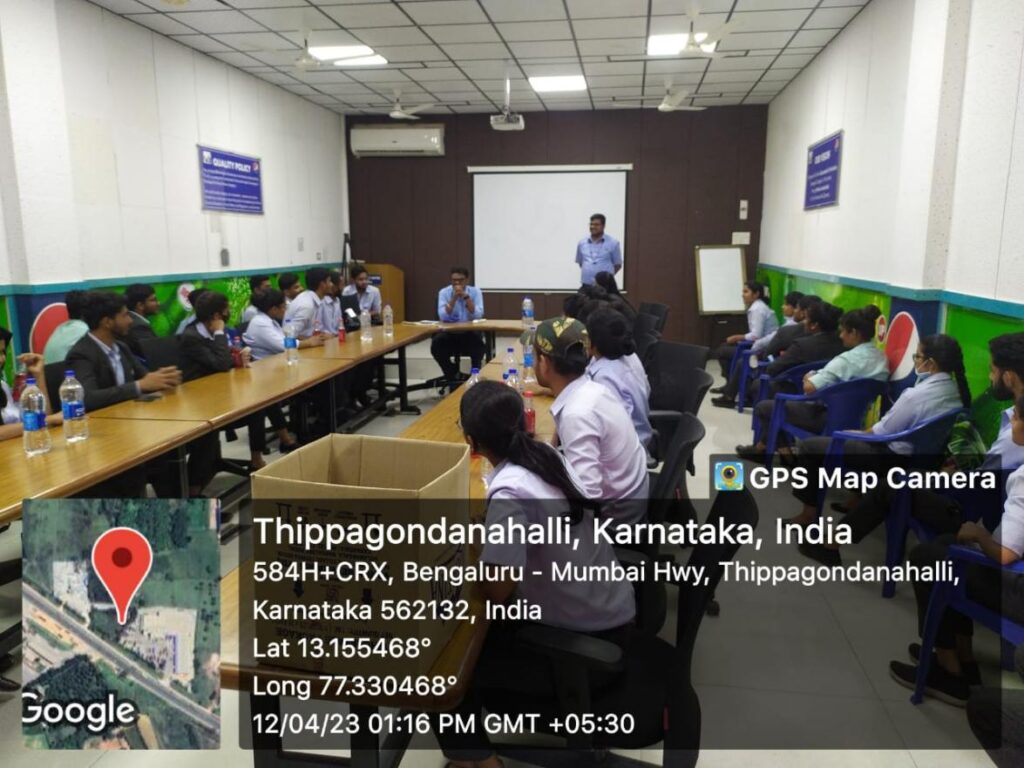

Mr. Umesh Kumar, Quality Assurance Executive at Varun Beverages Ltd received us at the security room. We proceeded towards the Board Room for refreshments and offered chilled beverages, water, biscuits for consumption. The Production Manager Mr. Sajith Shetty and Mr. Umesh Kumar oriented the about the History, Organization structure, Plant layout and Franchise model.

Varun Beverages Ltd. Being a part of Ravi Kant Jaipuria Corp has 2 plants in the state and spread across 27 states and 7 Union Territories in India with its presence overseas. Varun Beverages Ltd is associated with PepsiCo for over 2.5 decades and is the second largest franchise of PepsiCo.

The Plant in Nelamangala, is a bottling unit that manufactures Plastic bottles and Tetra packages for Beverages. The entire layout of the factory is categorized as per the product portfolio. Carbonated drinks, Fruit based beverages and Packaged drinking water are the prime categories. The plant manufactures and packages a variety of carbonated drinks like Pepsi, Pepsi Black, Mountain Dew, Sting, Seven-Up, Mirinda Orange etc, fruit based drinks like Tropicana Slice, Tropicana Juices etc. and packaged drinking water like Aquafina. The plant also has a separate warehouse for effective Inventory Management. All the raw materials are unloaded and stored with efficient quality checks.

The students were taken to the glass bottles unit and were told about the process of collection, cleaning and reuse of manufactured glass bottles. In the plastic bottles section they observed the conveyor belt and were informed it’s capacity to produce 600 bottles every minute. The water for the entire facility is supplied after purification. The mixture of additives, preservatives, sugar, flavouring substances is added to purified water. The machines used for manufacturing is imported from Germany, however, the staffs are trained to operate, repair and maintain these machines. The plant is also designed to support appropriate infrastructure and equipment to avoid pests. There is regular pest control checks and drives performed by third party organization for the entire plant layout.

The demand is managed based on the seasons and special requirements through predictive analysis.The supply of all the beverages takes place through the wholesaler, and further from there the beverages are supplied through agents as per the retailers or the customer’s requirements.The entire

manufacturing process is divided into cost units at each stage and cost control measures are applied with rigorous monitoring of wastage, leakage, defects with maximum efficiency each cycle.

The students had the opportunity to raise queries at every stage. The responses gained were acknowledged by all the students. We were glad to receive the chance to learn and interact with the professionals. Students and Faculty Coordinator shared the feedback and expressed their gratitude to the staff. All participants thoroughly enjoyed the Industrial Visit.

Photos of the Industrial Visit